CCGW060202 Standard PCBN Carbide Turning PCBN Cutting Insert for hardened steel

PCBN Insert Description:

Polycrystalline cubic boron nitride (CBN) is a material with excellent hot hardness that can be used at very high

cutting speeds. It also exhibits good toughness and thermal shock resistance.

PCBN insert (Polycrystalline cubic boron nitride) is used in machining operations to cut and shape hard

and abrasive materials such as hardened steel, cast iron, and powder metallurgy.

MANANOVA PCBN Insert: Worldia Standard portfolio

MANANOVA is the name for Worldia‘s stock-keeping standard product portfolio.

It provides best-in-class high-quality products within a wide range of most-common

applications at very attractive prices.

Each item has an inventory code which simplifies the order process.

Main products:

PCD inserts

Providing stable, universal, highly efficient cutting effect.

PCBN inserts

Universal for hardened steel, cast iron, ductile iron, and powder metallurgy.

PCBN Insert Application:

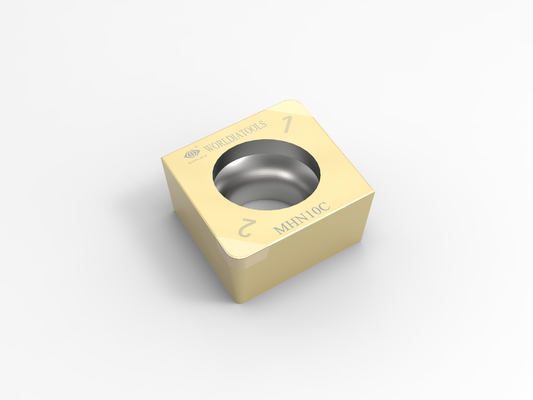

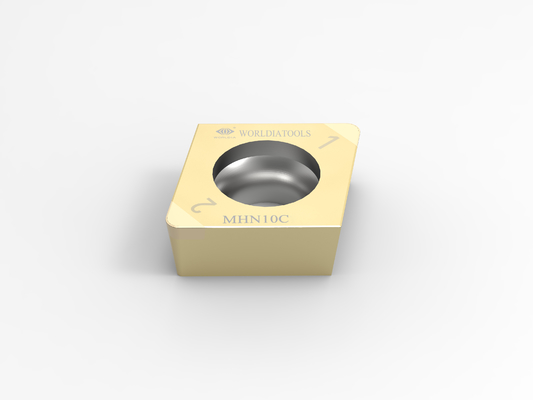

| MHN10C |

Applied to the continuous cutting of hardened steel |

| MHN20C |

Applied to medium interrupted cutting of hardened steel |

| MHN30C |

Applied to the heavy interrupted cutting of hardened steel |

PCBN Insert Specification:

Material Introduction - Easy choice for CBN Grade

ISO H: Hardened Steel Continuous cutting

ISO K: Cast Iron Light interrupted cutting

ISO S: Powder Metallurgy Heavy interrupted cutting

| Material |

ISO H |

ISO K |

ISO S |

| PCBN Grade |

MHN10C |

MHN20C |

MNH30C |

MKN10 |

MKN20 |

MSN10 |

MSN20 |

| Smooth |

Moderate |

Toughness |

Cast Iron |

Ductile Iron |

Powder Metallurgy |

Powder Metallurgy |

| Vc |

180(150~250)

m/min |

100(50~150)

m/min |

80(30~120)

m/min |

600(300~800)

m/min |

300(150~450)

m/min |

300(200~500)

m/min |

500(300~800)

m/min |

| fn |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

| % |

45~55 |

60~70 |

85~95 |

85~95 |

60~70 |

60~70 |

85~95 |

| Grain size |

1~2 um |

1~2 um |

2~3um |

2~3 um |

1~2 um |

1~2 um |

2~3 um |

| Bond |

TiC |

TiN |

Co/W |

Co/W |

TiCN |

TiCN |

Co/W |

| CCGW |

Shape |

Dimensions |

| ANSI Code |

ISO Code |

Tips |

IC

mm |

S

mm |

R

mm |

Φd

mm |

LE

mm |

All

Stocked |

CCGW 21.50.5 |

CCGW 060202 |

2N |

6.35 |

2.38 |

0.2 |

2.8 |

2.2 |

| CCGW 21.51 |

CCGW 060204 |

2N |

6.35 |

2.38 |

0.4 |

2.8 |

2.2 |

| CCGW 21.52 |

CCGW 060208 |

2N |

6.35 |

2.38 |

0.8 |

2.8 |

2.2 |

| |

|

|

|

|

|

|

|

| CCGW 32.50.5 |

CCGW 09T302 |

2N |

9.525 |

3.97 |

0.2 |

4.4 |

2.2 |

| CCGW 32.51 |

CCGW 09T304 |

2N |

9.525 |

3.97 |

0.4 |

4.4 |

2.2 |

| CCGW 32.52 |

CCGW 09T308 |

2N |

9.525 |

3.97 |

0.8 |

4.4 |

2.2 |

| CCGW 32.53 |

CCGW 09T312 |

2N |

9.525 |

3.97 |

1.2 |

4.4 |

2.2 |

PCBN Insert Manufacturing & Inspection Process

About Worldia:

Bejing Worldia Diamond Tools Co.,Ltd. was established in the year 2006.As a national Hi-Tech enterprise,

Worldia focuses on R&D, Production, and Sales and Service of high-precision cutting tools.

Our products mainly cover high-precision PCBN/PCD/CVD cutting tools, solid carbide tools,

holders as well as PCD/CVD materials.

Financial Strength, Team Spirit And Integrity

Enabler Of Our Growth

Made In China For The World

Meeting High Quality And Performance Standards

Global Service Capabilities

Key To Supporting Our Customers

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!