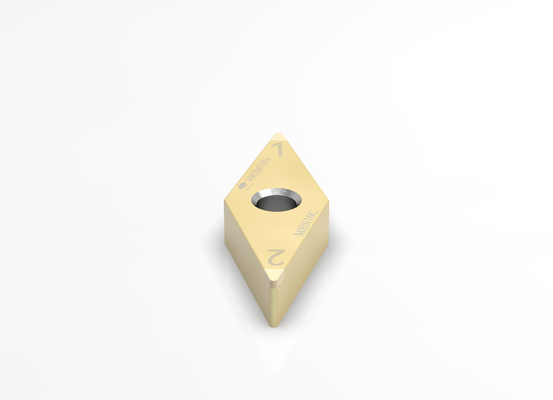

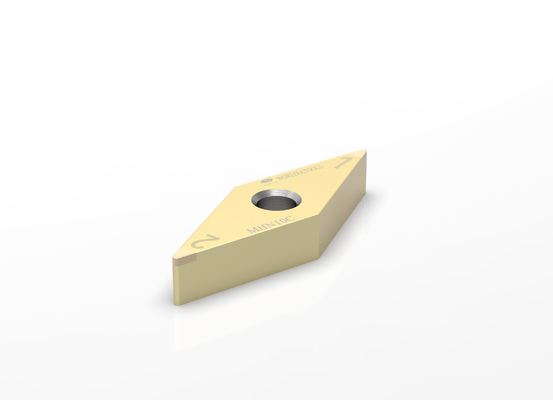

VNGA160402 Coated CBN Carbide Turning Insert CBN Cutting Insert for hardened steel

Material:

Tools with Poly-Crystalline Diamond (PCD) cutting materials can reduce your tooling cost significantly,

PCD tools are ideal for use with non-ferrous metal.

Polycrystalline cubic boron nitride(CBN) is a material with an excellent hot hardness that can be used

at very high cutting speeds.

Description:

"ManaNova" is a sub-brand of Worldia, focusing on the high-end standard series.

we strictly choose PCD and PCBN materials to provide the universal cutting effect.

The key feature of ManaNova is Easy choice and Fast delivery.

"Easy choice": It is easy to choose according to the comparison table and application.

"Fast delivery": All the types of ManaNova PCD Inserts in the catalog are available in stock.

Eliminating force majeure, you can get within 4-5 days.

Main products:

PCBN insert:7material/ 1 type, universal for hardened steel, cast iron, ductile iron, and powder metallurgy.

PCD insert: Suitable for rough and finish machining of aluminum alloy and other non-ferrous metal materials.

Advantages:

· Universal

· Easy choice

· Fast delivery

Service:

· Online store service

· Local distributor support

· Technical support

Application:

Worldia ManaNova series covers 7 high-quality CBN grades for the processing of hardened steel,

cast iron, and powder metallurgy, the available grades are MHN10C, MHN20C, MHN30C,

MKN10, MKN20, MSN10, MSN20.

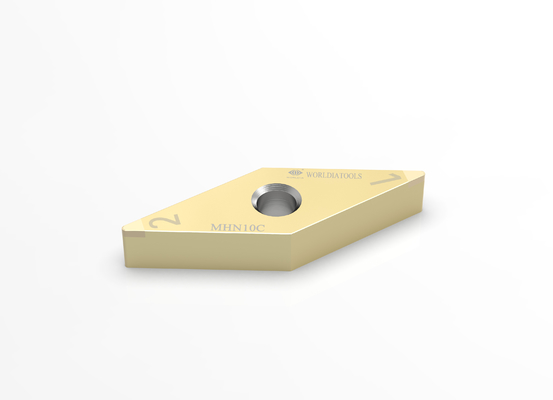

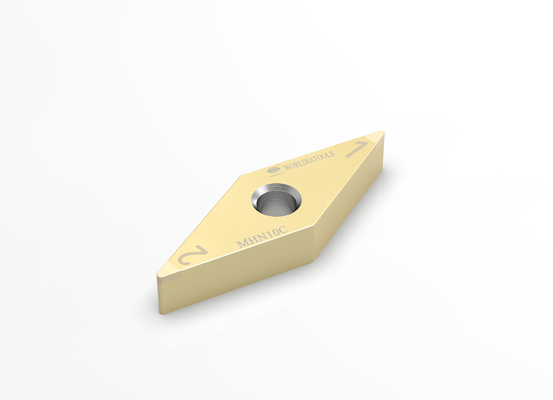

| MHN10C |

Applied to the continuous cutting of hardened steel |

| MHN20C |

Applied to medium interrupted cutting of hardened steel |

| MHN30C |

Applied to the heavy interrupted cutting of hardened steel |

| MKN10 |

Applied to the cutting of gray cast iron |

| MKN20 |

Applied to the cutting of ductile iron |

| MSN10 |

Applied to the cutting of powder metallurgy |

| MSN20 |

Applied to the cutting of powder metallurgy |

Specification:

| Material |

ISO H |

ISO K |

ISO S |

| PCBN Grade |

MHN10C |

MHN20C |

MNH30C |

MKN10 |

MKN20 |

MSN10 |

MSN20 |

| Smooth |

Moderate |

Toughness |

Cast Iron |

Ductile Iron |

Powder Metallurgy |

Powder Metallurgy |

| Vc |

180(150~250)

m/min |

100(50~150)

m/min |

80(30~120)

m/min |

600(300~800)

m/min |

300(150~450)

m/min |

300(200~500)

m/min |

500(300~800)

m/min |

| fn |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

| % |

45~55 |

60~70 |

85~95 |

85~95 |

60~70 |

60~70 |

85~95 |

| Grain size |

1~2 um |

1~2 um |

2~3um |

2~3 um |

1~2 um |

1~2 um |

2~3 um |

| Bond |

TiC |

TiN |

Co/W |

Co/W |

TiCN |

TiCN |

Co/W |

| VNGA |

Shape |

Dimensions |

| ANSI Code |

ISO Code |

Tips |

IC

mm |

S

mm |

R

mm |

Φd

mm |

LE

mm |

All

Stocked |

VNGA 330.5 |

VNGA 160402 |

2N |

9.525 |

4.76 |

0.2 |

3.81 |

2.2 |

| VNGA 331 |

VNGA 160404 |

2N |

9.525 |

4.76 |

0.4 |

3.81 |

2.2 |

| VNGA 332 |

VNGA 160408 |

2N |

9.525 |

4.76 |

0.8 |

3.81 |

2.2 |

| VNGA 333 |

VNGA 160412 |

2N |

9.525 |

4.76 |

1.2 |

3.81 |

2.2 |

About Us:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!