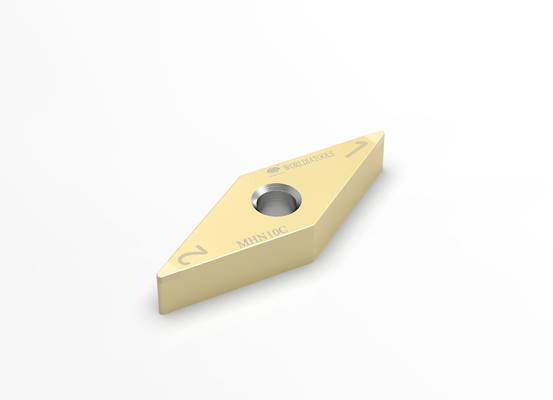

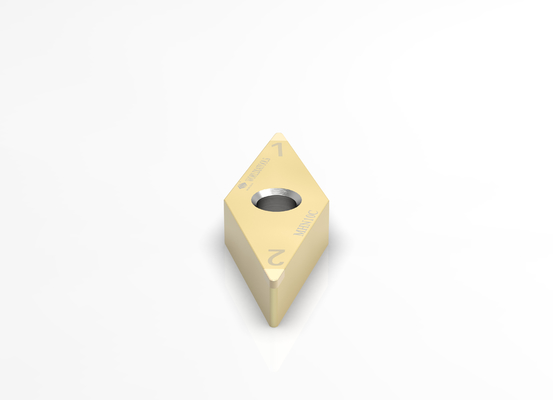

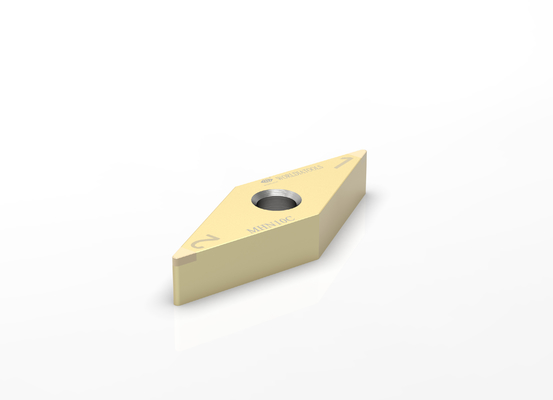

VNGA160412 Coated CBN Carbide Turning Insert CBN Cutting Insert for hardened steel

In the manufacturing worldia, changes push us to promote our products and service.

We are devoted to providing you with cutting tools and solutions that match the ambitions of your company.

We want to grow up with you together.

Description:

"ManaNova" is a sub-brand of Worldia, focusing on the high-end standard series, PCD/PCBN inserts are the main products.

The key feature of ManaNova is Easy choice and Fast delivery.

"Easy choice"

It is easy to choose according to the comparison table and application.

"Fast delivery"

All the types of ManaNova PCD Inserts in the catalog are available in stock.

Material:

Poly-Crystalline Diamond (PCD)

1. Reduce your tooling cost significantly

2. For non-ferrous metal machining

Polycrystalline cubic boron nitride(CBN)

1. With an excellent hot hardness

2. Good toughness and thermal shock resistance.

3. For hardened steel, cast irons, sintered irons as well as powder metallurgy components machining

Main products:

PCBN inserts

7material/ 1 type, universal for hardened steel, cast iron, ductile iron, and powder metallury.

PCD insert

Providing stable, universal, high efficient cutting effect.

Advantages:

· Universal

· Easy choice

· Fast delivery

Application:

| MHN10C |

Applied to the continuous cutting of hardened steel |

| MHN20C |

Applied to medium interrupted cutting of hardened steel |

| MHN30C |

Applied to the heavy interrupted cutting of hardened steel |

| MKN10 |

Applied to the cutting of gray cast iron |

| MKN20 |

Applied to the cutting of ductile iron |

| MSN10 |

Applied to the cutting of powder metallurgy |

| MSN20 |

Applied to the cutting of powder metallurgy |

Specification:

| Material |

ISO H |

ISO K |

ISO S |

| PCBN Grade |

MHN10C |

MHN20C |

MNH30C |

MKN10 |

MKN20 |

MSN10 |

MSN20 |

| Smooth |

Moderate |

Toughness |

Cast Iron |

Ductile Iron |

Powder Metallurgy |

Powder Metallurgy |

| Vc |

180(150~250)

m/min |

100(50~150)

m/min |

80(30~120)

m/min |

600(300~800)

m/min |

300(150~450)

m/min |

300(200~500)

m/min |

500(300~800)

m/min |

| fn |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

| % |

45~55 |

60~70 |

85~95 |

85~95 |

60~70 |

60~70 |

85~95 |

| Grain size |

1~2 um |

1~2 um |

2~3um |

2~3 um |

1~2 um |

1~2 um |

2~3 um |

| Bond |

TiC |

TiN |

Co/W |

Co/W |

TiCN |

TiCN |

Co/W |

| VNGA |

Shape |

Dimensions |

| ANSI Code |

ISO Code |

Tips |

IC

mm |

S

mm |

R

mm |

Φd

mm |

LE

mm |

All

Stocked |

VNGA 330.5 |

VNGA 160402 |

2N |

9.525 |

4.76 |

0.2 |

3.81 |

2.2 |

| VNGA 331 |

VNGA 160404 |

2N |

9.525 |

4.76 |

0.4 |

3.81 |

2.2 |

| VNGA 332 |

VNGA 160408 |

2N |

9.525 |

4.76 |

0.8 |

3.81 |

2.2 |

| VNGA 333 |

VNGA 160412 |

2N |

9.525 |

4.76 |

1.2 |

3.81 |

2.2 |

About Us:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!