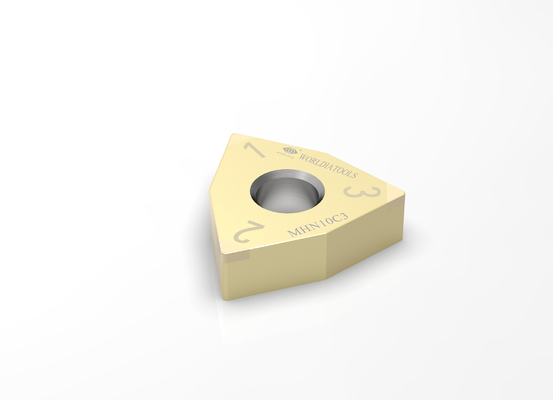

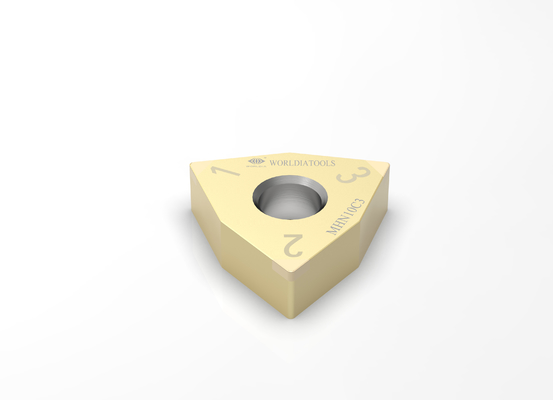

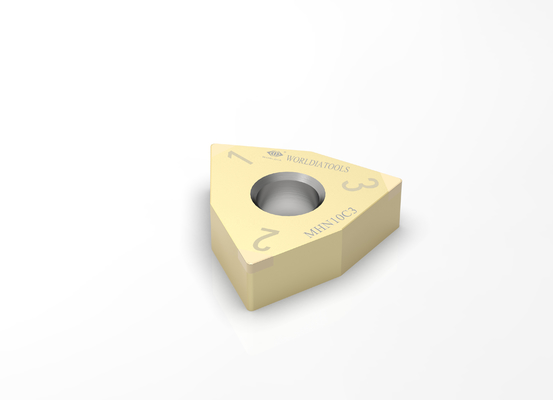

WNGA080404 Coated CBN Carbide Turning Insert CBN Cutting Insert for hardened steel

Description:

"ManaNova" is a sub-brand of Worldia, focusing on the high-end standard series.

ManaNova is a concept that stands in the view of end-users, we strictly choose PCD and PCBN materials

to provide the universal cutting effect.

MANANOVA takes “Easy choice and Fast delivery” as the feature, which intends to provide fast and efficient

service for domestic and foreign customers to meet their demand for standardized and universalized tools.

Main products:

PCBN insert: material/ 1 type, universal for hardened steel, cast iron, ductile iron, and powder metallurgy.

“Seven material/ one type” namely each specification corresponding to seven materials

(MHN10C ,MHN20C ,MHN30C, MKN10,MKN20,MSN 10)is the feature of the PCBN insert.

PCD insert is suitable for rough and finish machining of aluminum alloy and other non-ferrous metal materials.

PCD insert provides a stable, universal, high efficient cutting effect.

Advantages:

· Universal

· Easy choice

· Fast delivery

Service:

· Online store service

· Local distributor support

· Technical support

Application:

Worldia ManaNova series covers 7 high-quality CBN grades for the processing of hardened steel,

cast iron, and powder metallurgy, the available grades are MHN10C, MHN20C, MHN30C,

MKN10, MKN20, MSN10, and MSN20.

| MHN10C |

Applied to the continuous cutting of hardened steel |

| MHN20C |

Applied to medium interrupted cutting of hardened steel |

| MHN30C |

Applied to the heavy interrupted cutting of hardened steel |

| MKN10 |

Applied to the cutting of gray cast iron |

| MKN20 |

Applied to the cutting of ductile iron |

| MSN10 |

Applied to the cutting of powder metallurgy |

| MSN20 |

Applied to the cutting of powder metallurgy |

Specification:

| Material |

ISO H |

ISO K |

ISO S |

| PCBN Grade |

MHN10C |

MHN20C |

MNH30C |

MKN10 |

MKN20 |

MSN10 |

MSN20 |

| Smooth |

Moderate |

Toughness |

Cast Iron |

Ductile Iron |

Powder Metallurgy |

Powder Metallurgy |

| Vc |

180(150~250)

m/min |

100(50~150)

m/min |

80(30~120)

m/min |

600(300~800)

m/min |

300(150~450)

m/min |

300(200~500)

m/min |

500(300~800)

m/min |

| fn |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

| % |

45~55 |

60~70 |

85~95 |

85~95 |

60~70 |

60~70 |

85~95 |

| Grain size |

1~2 um |

1~2 um |

2~3um |

2~3 um |

1~2 um |

1~2 um |

2~3 um |

| Bond |

TiC |

TiN |

Co/W |

Co/W |

TiCN |

TiCN |

Co/W |

| WNGA |

Shape |

Dimensions |

| ANSI Code |

ISO Code |

Tips |

IC

mm |

S

mm |

R

mm |

Φd

mm |

LE

mm |

All

Stocked |

WNGA 431 |

WNGA 080404 |

3N |

12.7 |

4.76 |

0.4 |

5.16 |

2.2 |

| WNGA 432 |

WNGA 080408 |

3N |

12.7 |

4.76 |

0.8 |

5.16 |

2.2 |

About Us:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!