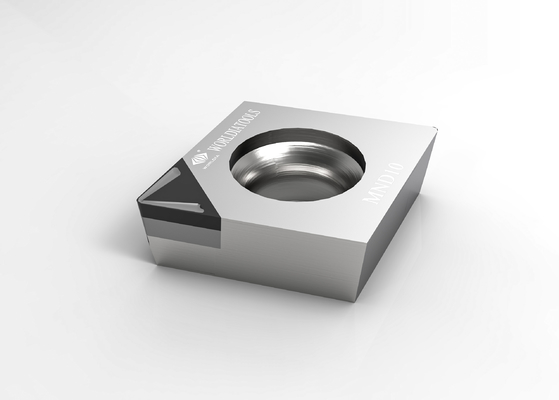

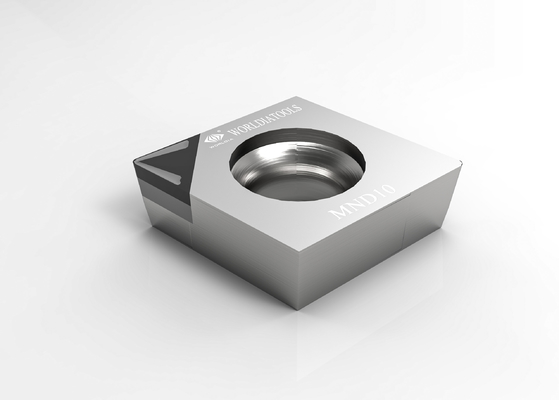

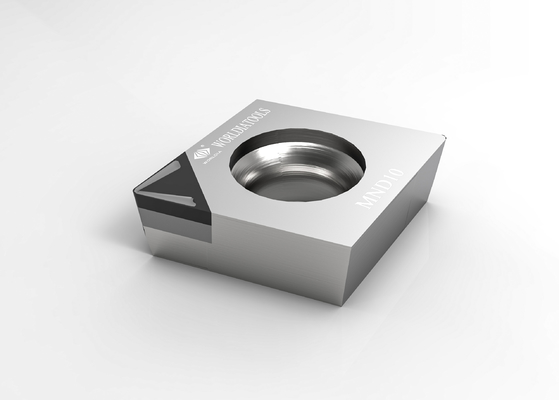

C-CCGW 09T304 Standard Carbide Turning PCD Cutting Insert for non-ferrous materials

Description:

"ManaNova" is a sub-brand of Worldia, focusing on the high-end standard series.

ManaNova is a concept that stands in the view of end-users, we strictly choose PCD and PCBN materials

to provide the universal cutting effect.

MANANOVA takes “Easy choice and Fast delivery” as the feature, which intends to provide fast and efficient

service for domestic and foreign customers to meet their demand for standardized and universalized tools.

Advantages:

The Worldia PCD insert is distinguished for high hardness, high compressive strength,

large thermal conductivity, and good wear resistance.

It operates with high processing accuracy and large efficiency at high speed.

PCD Insert with chip-breaker has an excellent chip breaking in finishing machining

Material:

Tools with Poly-Crystalline Diamond (PCD) cutting materials can reduce your tooling cost significantly,

PCD tools are ideal for the use with non-ferrous metal, such as aluminum, Zinc, and magnesium alloys,

GRP composites, carbon fiber reinforced plastics, “green” carbide, and ceramic as well as all abrasive materials.

Application:

| MND10 |

Applied to the cutting of non-ferrous materials such as aluminum alloys, etc. |

Main products:

PCD insert is suitable for rough and finish machining of aluminum alloy and other non-ferrous metal materials.

PCBN insert 7material/ 1 type, universal for hardened steel, cast iron, ductile iron, and powder metallurgy.

Advantages:

· Universal

· Easy choice

· Fast delivery

Specification:

| CCGW |

Dimensions |

Grade |

| ANSI Code |

ISO Code |

Tips |

IC

mm |

S

mm |

R

mm |

Φd

mm |

LE

mm |

MND

10 |

| CCGW 21.50.5 |

CCGW 060202 |

1N |

6.35 |

2.38 |

0.2 |

2.8 |

2.5 |

√ |

| CCGW 21.51 |

CCGW 060204 |

1N |

6.35 |

2.38 |

0.4 |

2.8 |

2.5 |

√ |

| CCGW 32.50.5 |

CCGW 09T302 |

1N |

9.525 |

3.97 |

0.2 |

4.4 |

2.5 |

√ |

| CCGW 32.51 |

CCGW 09T304 |

1N |

9.525 |

3.97 |

0.4 |

4.4 |

2.5 |

√ |

| CCGW 32.52 |

CCGW 09T308 |

1N |

9.525 |

3.97 |

0.8 |

4.4 |

2.5 |

√ |

| |

| C-CCGW 21.50.5 |

C-CCGW 060202 |

1N |

6.35 |

2.38 |

0.2 |

2.8 |

2.5 |

√ |

| C-CCGW 32.51 |

C-CCGW 09T304 |

1N |

9.525 |

3.97 |

0.4 |

4.4 |

2.5 |

√ |

| |

| F-CCGW 21.51 |

F-CCGW 060204 |

2N |

6.35 |

2.38 |

0.4 |

2.8 |

6.4 |

√ |

Recommendation:

| Feed rate recommendation |

| Nose radius(mm) |

Ra um |

| 0.2 |

0.4 |

0.8 |

1.6 |

3.2 |

6.4 |

| Feed Rate f (mm/rev)≤ |

| 0.2 |

0.028 |

0.040 |

0.057 |

0.080 |

0.113 |

0.160 |

| 0.4 |

0.040 |

0.057 |

0.080 |

0.113 |

0.160 |

0.226 |

| 0.8 |

0.057 |

0.080 |

0.113 |

0.160 |

0.226 |

0.320 |

| 1.2 |

0.069 |

0.098 |

0.139 |

0.196 |

0.277 |

0.392 |

| 1.6 |

0.080 |

0.113 |

0.160 |

0.226 |

0.320 |

0.453 |

| 2.4 |

0.098 |

0.139 |

0.196 |

0.277 |

0.392 |

0.554

|

About Us:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!