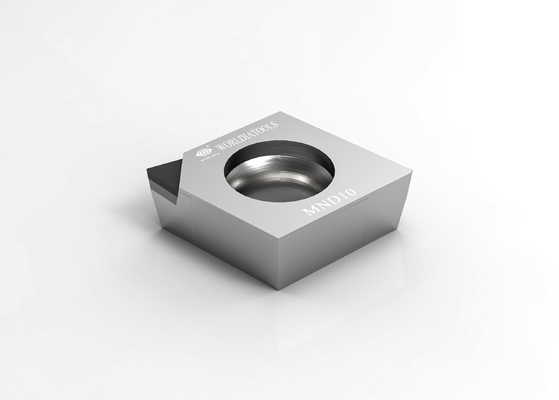

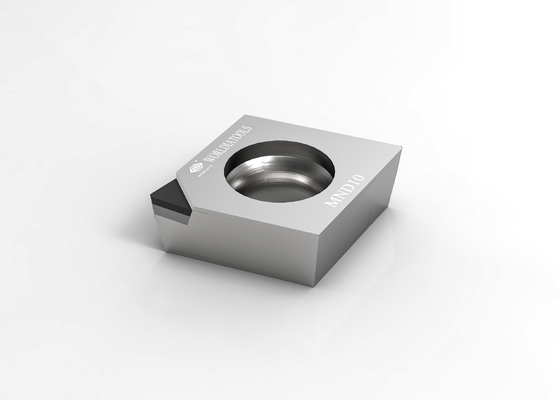

CCGT09T304 Standard Carbide Turning PCD Cutting Insert for non-ferrous materials

PCD INSERT DESCRIPTION:

PCD stands for Polycrystalline Diamond, which is a synthetic material that is extremely hard and wear-resistant.

PCD inserts are widely used in the machining of non-ferrous metals such as aluminum, copper, and brass,

as well as non-metallic materials such as ceramics, reinforced plastics, and composites.

PCD INSERT ADVANTAGES:

1.PCD Inserts are extremely hard and wear-resistant, which means they can last much longer than other types of cutting tools.

2.PCD Inserts also provide superior surface finish and dimensional accuracy, which is important in many high-precision machining applications.

3.PCD inserts are also highly heat-resistant, which makes them ideal for high-speed machining operations where high temperatures are generated.

PCD STANDARD INSERTS: MANANOVA SERIES

MANANOVA is the name for Worldia‘s stock-keeping standard product portfolio.

It provides best-in-class high-quality products within a wide range of most-common applications at very attractive prices.

Each item has an inventory code which simplifies the order process.

MANANOVA products will be delivered directly from our warehouses to any global destination within max. 1 week.

Main products:

PCD inserts are ideal for the use with non-ferrous metal, such as aluminum, Zinc and magnesium alloys,

GRP composites, carbon fiber reinforced plastics, “green” carbide, and ceramic as well as all abrasive materials.

CBN inserts are ideal for the use with hardened steel, cast irons, and sintered irons as well as

powder metallurgy components.

PCD INSERT SPECIFICATION:

| Angle |

Dimensions |

Grade |

| ANSI Code |

ISO Code |

Tips |

IC

mm |

S

mm |

R

mm |

Φd

mm |

LE

mm |

MND

10 |

| CCGT 21.50.5 |

CCGT 060202 |

1N |

6.35 |

2.38 |

0.2 |

2.8 |

2.5 |

√ |

| CCGT 21.51 |

CCGT 060204 |

1N |

6.35 |

2.38 |

0.4 |

2.8 |

2.5 |

√ |

| |

| CCGT 32.50.5 |

CCGT 09T302 |

1N |

9.525 |

3.97 |

0.2 |

4.4 |

2.5 |

√ |

| CCGT 32.51 |

CCGT 09T304 |

1N |

9.525 |

3.97 |

0.4 |

4.4 |

2.5 |

√ |

| CCGT 32.52 |

CCGT 09T308 |

1N |

9.525 |

3.97 |

0.8 |

4.4 |

2.5 |

√

|

For another ISO Code, please get in touch with us!

PCD INSERT APPLICATION:

| MND10 |

Applied to the cutting of non-ferrous materials such as aluminum alloys, etc. |

PCD tools are limited to non-ferrous materials, such as high-silicon aluminum, metal matrix composites (MMC), and carbon fiber reinforced plastics (CFRP).

PCD with flood coolant can also be used in titanium super-finishing applications. |

| ·Aluminum and aluminum alloys |

| ·Copper, brass, and bronze alloys |

| ·Zinc and magnesium alloys |

| ·Carbon Fiber |

| ·Epoxy resins |

| ·Plastics |

| ·Fiberglass composites |

| ·Graphite composites |

PCD INSERT SERVICE:

· Online store service

· Local distributor support

· Technical support

| Feed rate recommendation |

| Nose radius(mm) |

Ra um |

| 0.2 |

0.4 |

0.8 |

1.6 |

3.2 |

6.4 |

| Feed Rate f (mm/rev)≤ |

| 0.2 |

0.028 |

0.040 |

0.057 |

0.080 |

0.113 |

0.160 |

| 0.4 |

0.040 |

0.057 |

0.080 |

0.113 |

0.160 |

0.226 |

| 0.8 |

0.057 |

0.080 |

0.113 |

0.160 |

0.226 |

0.320 |

| 1.2 |

0.069 |

0.098 |

0.139 |

0.196 |

0.277 |

0.392 |

| 1.6 |

0.080 |

0.113 |

0.160 |

0.226 |

0.320 |

0.453 |

| 2.4 |

0.098 |

0.139 |

0.196 |

0.277 |

0.392 |

0.554 |

CUSTOMER REVIEW OF PCD INSERT

ABOUT WORLDIA

Beijing Worldia Diamond Tools Co., Ltd was established in 2006. As a national hi-tech enterprise,

Worldia focuses upon R & D, production, sales and service of high precision diamond cutting tools.

Our products include high-precision PCD/PCBN/CVDD cutting tools, solid carbide cutting tools,

diamond scribing wheels and related accessories.The cutting tools we provide have been widely

applied in automotive, electronic, new energy, and other industries.

COMPANY HISTORY

MADE IN CHINA FOR THE WORLD

Research and development, design, manufacturing,application and reconditioning expertise byhighly-qualified,

diverse and motivated team of1100 employees, thereof 150 R&D,1 PhD, 100Graduate Engineers, >30% female team members.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!