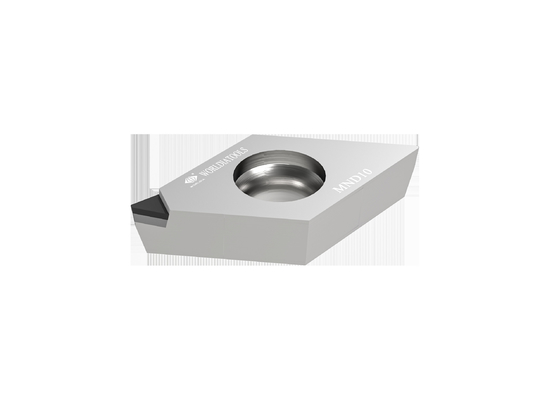

DCGT11T308 Carbide Turning Insert PCD Cutting Insert for non-ferrous materials

As a high-end standard cutting tool series, MANANOVA carries out the whole process of

quality management from raw materials, with sophisticated production testing equipment,

professional and experienced R&D and production team, and professional technical services,

so that every user can continue to experience Worldia cutting tools advantages.

Material:

Poly-Crystalline Diamond (PCD)

1. Reduce your tooling cost significantly

2. For non-ferrous metal machining

Polycrystalline cubic boron nitride(CBN)

1. With an excellent hot hardness

2. Good toughness and thermal shock resistance.

3. For hardened steel, cast irons, sintered irons as well as powder metallurgy components machining

Description:

ManaNova, a sub-brand of Worldia, is positioned as a high-end standard series.

To meet the needs of customers as the goal, we strictly select PCD/PCBN materials to provide a universal,

stable, and efficient cutting effect.

The critical feature of ManaNova is Easy choice and Fast delivery.

Main products:

PCBN insert is suitable for machining hardened steel, gray cast iron, ductile iron, and powder metallurgy.

PCD insert (MND10 material ) is suitable for rough and finish machining of aluminum alloy and other non-metal materials.

Advantages:

·High quality

·Low cost

·Factory direct supply

Service:

· Online store service

· Local distributor support

· Technical support

Application:

| MND10 |

For the cutting of non-ferrous materials such as aluminum alloys, etc. |

PCD tools are limited to non-ferrous materials, such as high-silicon aluminum, metal matrix composites (MMC), and carbon fiber reinforced plastics (CFRP).

PCD with flood coolant can also be used in titanium super-finishing applications. |

| ·Aluminum and aluminum alloys |

| ·Copper, brass, and bronze alloys |

| ·Zinc and magnesium alloys |

| ·Carbon Fiber |

| ·Epoxy resins |

| ·Plastics |

| ·Fiberglass composites |

| ·Graphite composites |

Specification:

| Angle |

Dimensions |

Grade |

| ANSI Code |

ISO Code |

Tips |

IC

mm |

S

mm |

R

mm |

Φd

mm |

LE

mm |

MND

10 |

| DCGT 21.50.5 |

DCGT 070202 |

1N |

6.35 |

2.38 |

0.2 |

2.8 |

2.5 |

√ |

| DCGT 21.51 |

DCGT 070204 |

1N |

6.35 |

2.38 |

0.4 |

2.8 |

2.5 |

√ |

| |

| DCGT 32.50.5 |

DCGT 11T302 |

1N |

9.525 |

3.97 |

0.2 |

4.4 |

2.5 |

√ |

| DCGT 32.51 |

DCGT 11T304 |

1N |

9.525 |

3.97 |

0.4 |

4.4 |

2.5 |

√ |

| DCGT 32.52 |

DCGT 11T308 |

1N |

9.525 |

3.97 |

0.8 |

4.4 |

2.5 |

√ |

| Feed rate recommendation |

| Nose radius(mm) |

Ra um |

| 0.2 |

0.4 |

0.8 |

1.6 |

3.2 |

6.4 |

| Feed Rate f (mm/rev)≤ |

| 0.2 |

0.028 |

0.040 |

0.057 |

0.080 |

0.113 |

0.160 |

| 0.4 |

0.040 |

0.057 |

0.080 |

0.113 |

0.160 |

0.226 |

| 0.8 |

0.057 |

0.080 |

0.113 |

0.160 |

0.226 |

0.320 |

| 1.2 |

0.069 |

0.098 |

0.139 |

0.196 |

0.277 |

0.392 |

| 1.6 |

0.080 |

0.113 |

0.160 |

0.226 |

0.320 |

0.453 |

| 2.4 |

0.098 |

0.139 |

0.196 |

0.277 |

0.392 |

0.554 |

About Us:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!