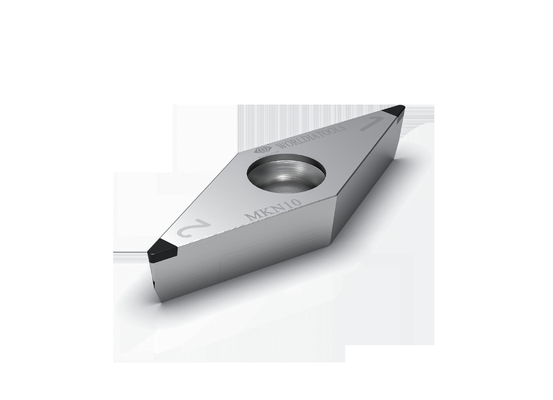

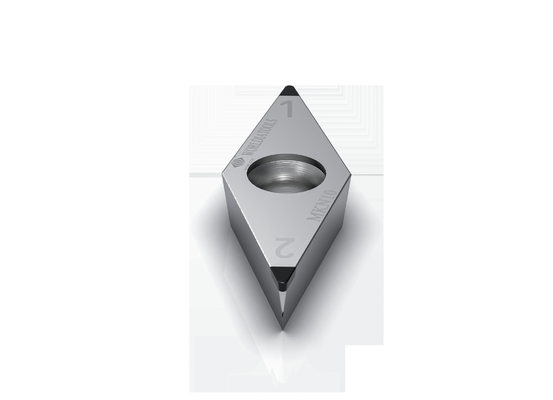

VCGW Standard PCBN Carbide Turning Insert PCBN Cutting Insert for powder metallurgy

PCBN CUTTING INSERT DESCRIPITION:

PCBN stands for Polycrystalline Cubic Boron Nitride,

which is a synthetic material that is extremely hard and is used as a cutting tool material.

A PCBN cutting insert is a type of cutting tool that is used in various machining processes, including turning, milling, and drilling.

PCBN Cutting inserts are used for machining for hardened steel,cast iron and powder metallurgy.

STANDARD PCBN CUTTING INSERT: WORLDIA MANANOVA SERIES

MANANOVA is the name for Worldia‘s stock-keeping standard product portfolio.

It provides best-in-class high-quality products within a wide range of most-common applications at very attractive prices.

Each item has an inventory code which simplifies the order process.

Main products:

PCBN Cutting Insert:insert: PCBN cutting insertstools are ideal for the use with hardened steel,cast irons

and sintered irons as well as powder metallurgy components.

PCD Cutting Insert: PCD cutting inserts can be used in many fields including car industry, energy equipment,

and the wood and stone

industry. It can be used to cut and process different materials such as nonferrous metal, tungsten carbide, ceramic,

nonmetal and composite material.

ADVANTAGES OF PCBN CUTTING INSERT

· Universal

· Easy choice

· Fast delivery

Service OF PCBN CUTTING INSERT:

· Online store service

· Local distributer support

· Technical support

APPLICATION OF CUTTING INSERT:

| MHN10C |

Applied to continuous cutting of hardened steel |

| MHN20C |

Applied to medium interrupted cutting of hardened steel |

| MHN30C |

Applied to heavy interrupted cutting of hardened steel |

| MKN10 |

Applied to cutting of gray cast iron |

| MKN20 |

Applied to cutting of ductile iron |

| MSN10 |

Applied to cutting of powder metallurgy |

| MSN20 |

Applied to cutting of powder metallurgy |

SPECIFICATION OF CUTTING INSERT:

Material Introduction - Easy choice for CBN Grade

ISO H:Hardened Steel Continuous cutting

ISO K: Cast Iron Light interrupted cutting

ISO S: Powder Metallurgy Heavy interrupted cutting

| Material |

ISO H |

ISO K |

ISO S |

| PCBN Grade |

MHN10C |

MHN20C |

MNH30C |

MKN10 |

MKN20 |

MSN10 |

MSN20 |

| Smooth |

Moderate |

Toughness |

Cast Iron |

Ductile Iron |

Powder Metallurgy |

Powder Metallurgy |

| Vc |

180(150~250)

m/min |

100(50~150)

m/min |

80(30~120)

m/min |

600(300~800)

m/min |

300(150~450)

m/min |

300(200~500)

m/min |

500(300~800)

m/min |

| fn |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.2)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

0.1(0.03~0.3)

mm/r |

| % |

45~55 |

60~70 |

85~95 |

85~95 |

60~70 |

60~70 |

85~95 |

| Grain size |

1~2 um |

1~2 um |

2~3um |

2~3 um |

1~2 um |

1~2 um |

2~3 um |

| Bond |

TiC |

TiN |

Co/W |

Co/W |

TiCN |

TiCN |

Co/W |

| VCGW |

Shape |

Dimensions |

| ANSI Code |

ISO Code |

Tips |

IC

mm |

S

mm |

R

mm |

Φd

mm |

LE

mm |

All

Stocked |

VCGW 221 |

VCGW 110304 |

2N |

6.35 |

3.18 |

0.4 |

2.8 |

2.2 |

| VCGW 222 |

VCGW 110308 |

2N |

6.35 |

3.18 |

0.8 |

2.8 |

2.2 |

| |

| VCGW 331 |

VCGW 160404 |

2N |

9.525 |

4.76 |

0.4 |

4.4 |

2.2 |

| VCGW 332 |

VCGW 160408 |

2N |

9.525 |

4.76 |

0.8 |

4.4 |

2.2 |

CUSTOMER REVIEW OF PCBN CUTTING INSERT

About WORLDIA:

FINANCIAL STRENGTH, TEAM SPIRIT AND INTEGRITY

MADE IN CHINA FOR THE WORLD

MEETING HIGH QUALITY AND PERFORMANCE STANDARDS

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!